How to choose a tool for wheel hub bearing unit?"High Efficiency of CBN Tool Hard Car"

How to choose a tool for wheel hub bearing unit?"High Efficiency of CBN Tool Hard Car"

Keywords wheel hub, CBN tool |2020-09-25 10:46:33

The development of hub bearing units in automobile industry is a pillar industry in Our country, which plays an important role in our national economy.As a very important part of automobile, hub bearing plays a vital role in the safety of automobile.With the rapid development of the automobile industry, wheel hub...

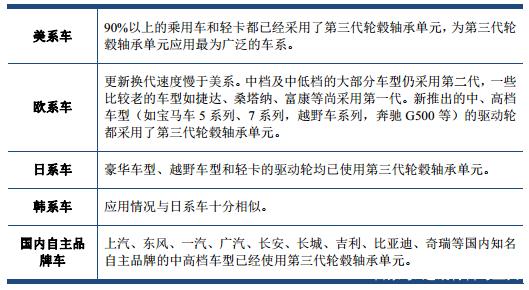

Development of hub bearing units

The automobile industry is the pillar industry of our country and plays a pivotal role in our national economy.As a very important part of automobile, hub bearing plays a vital role in the safety of automobile.With the rapid development of automobile industry, the wheel hub bearing unit has also been gradually update, from now to the third generation of the first generation of development, the third generation wheel hub bearing unit is the wheel hub bearing and the installation of the hub flange connection, the connecting flange of universal joint spindle and sensor integration as an assembly components, compared to the second generation of wheel hub bearing unit, the overall carrying capacity better, stronger rigidity, higher reliability, and built-in wheel speed sensor, realize the mechatronics development.At present, the third generation hub bearing unit has been adopted in many main vehicle systems at home and abroad.

Hub bearing unit

Automobile hub bearing unit

Wheel hub bearing unit to car instead of grinding tool selection

In the actual production and processing process, hub bearing units are generally quenched, because the hub bearing units after quenching have high hardness, high strength, and almost no plasticity.It is because of these characteristics of hub bearing, resulting in its processing of more difficult than ordinary steel coefficient.This puts forward more stringent requirements on the cutting tools for processing this kind of material.As a new process, the wheel hub bearing unit and other industries processing trend, the process of high efficiency, low cost, transmission technology can not compete with it.

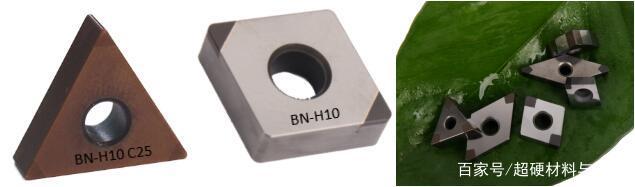

In view of the wheel hub bearing unit to car generation knife tools, at present mainly CBN cutting tools, such as BN - H05, BN - H10 material, its has high chemical stability, good thermal conductivity, made in the process of machining, heat of the material processed quickly passed out from the cutting point, reduce the thermal deformation of the workpiece, the cutting efficiency and improves the machining accuracy and service life of the cutter, is car generation of grinding wheel hub bearing units ideal hard tool.

At the same time, in order to meet the customer's higher tool life demand, also introduced BN-H05 C25, BN-H10 C25 coating CBN tool.The CBN tool is specially coated to reduce the friction force in contact with the workpiece, reduce the cutting force, reduce the friction heat generation in cutting, compared with the uncoated CBN tool, the coated CBN tool life at least more than 40%.

Hub bearing unit CBN tool

Test results of bN-H10 C25 coated CBN tool with wheel hub bearing instead of wheel grinding

Workpiece hardness: HRC58-62

Blade selection: BN-H10 C25

Cutting parameters: VC=180m/min, Fr=0.1mm/r, AP =0.15mm

Processing: dry cutting

Surface roughness: ≤Ra0.6.

Compared with traditional carbide tools, BN-H10 C25 coated CBN tools greatly improve the production efficiency, and the tool life is increased by 40% compared with uncoated CBN tools, which is an ideal cutting tool for hard turning hub bearing units.

Conclusion:

At present, China is striving for future industry 4.0 with high-end manufacturing represented by high-speed railway, manned space flight, new energy vehicles and artificial intelligence, seizing the high point of future industry, completing the overall surpassing of developed countries and realizing the great rejuvenation of the Chinese nation.However, these goals and plans are inseparable from the pursuit of each participant, as well as the excellence of every component and every process.Only through hard development and technological innovation can we truly overtake on the corner and become a real manufacturing power.Although it is difficult to achieve such a goal, but there is a long way to go, we are willing to work together.

✔Contact us, you will get more than what you see.

-All diamond tools can be ordered and fabricated!

Henry Wang | Quote Manager

-WhatsApp:+0086 134 5903 5657

-Email: ceo@zdiamondtools.com

-Web www.zdiamondtools.com

-Web www.zliontools.com

-Web www.stone-tool.com

-Web www.z-lion.com

English

English  Português

Português  русский

русский  Chinese

Chinese  French

French  Japanese

Japanese  Spanish

Spanish