Application and characteristics of diamond tools

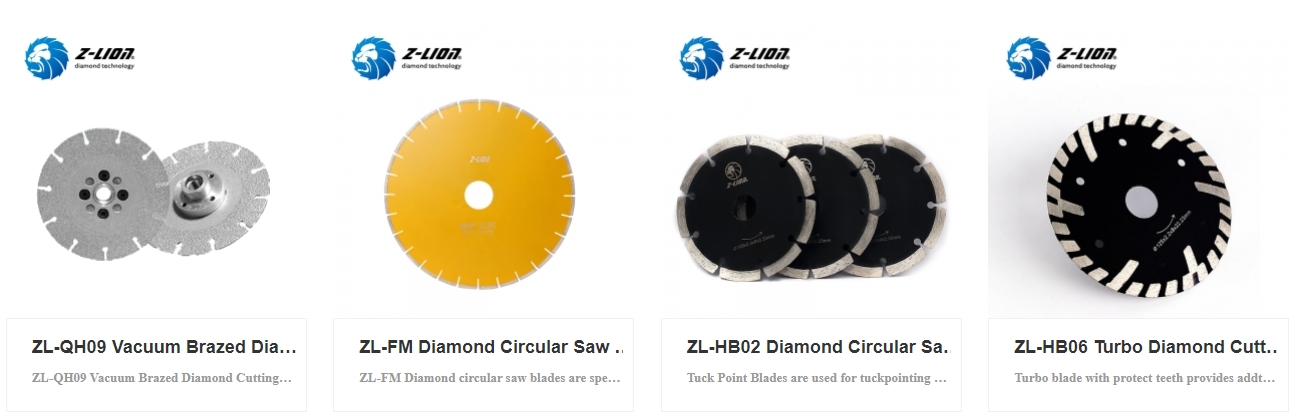

Diamond Cutting Tools

Diamond cutting tools such as diamond saw blades are widely used in the cutting of stone, ceramics, steel, concrete, glass, semiconductors, and other materials. Diamond's exceptional properties, including high wear resistance and hardness, make it an ideal material for cutting tools, enabling faster cutting speeds and increased efficiency in a variety of applications.

The use of diamond cutting tools has dramatically changed the cutting industry, providing unparalleled precision and durability. Unlike traditional cutting tools, diamond saw blades are designed to withstand high levels of stress and heat, making them ideal for heavy-duty cutting tasks. The ability of diamond cutting tools to maintain their shape and sharpness during cutting operations ensures consistent and precise results, even when working with the toughest materials.

One of the main advantages of diamond cutting tools is their versatility. They can be customized into a variety of shapes and sizes to meet specific cutting requirements, making them suitable for a variety of applications. Whether cutting complex stone designs or achieving precise cuts in steel and concrete, diamond cutting tools provide the flexibility needed to meet a variety of cutting challenges.

In the construction industry, diamond cutting tools play a vital role in the shaping and detailing of set floors and other concrete structures. Using a diamond saw blade allows you to precisely cut concrete, ensuring clean edges and a smooth surface. Additionally, with proper care and maintenance, diamond cutting tools handle floor hardness with ease, ensuring that the shine of polished concrete floors remains consistent over time.

In addition, the efficiency of diamond cutting tools enables a large number of cutting tasks to be completed in a relatively short period of time. This not only increases productivity but also reduces downtime, making diamond cutting tools a cost-effective solution for businesses and construction projects.

Diamond Grinding Tools

Diamond grinding tools have become essential equipment in various industries and have the characteristics of high efficiency, high precision, and stability in the processing of complex curved surfaces and hard materials. These tools include grinding discs, sandpaper, sanding belts, and more, and are widely used for grinding metal, ceramics, concrete, glass, and stone, providing unparalleled performance in materials processing applications.

The key characteristics of diamond grinding tools are their ability to provide exceptional precision and stability, making them suitable for a wide range of grinding tasks. Whether shaping complex designs on hard materials or achieving smooth surfaces on complex curves, diamond grinding tools provide the versatility and reliability needed to meet varying machining requirements.

The composition of diamond grinding tools is a key factor in their performance. These tools are manufactured using industrial diamond and metal powders at high temperatures and pressures, resulting in exceptional hardness and wear resistance. This unique composition enables diamond grinding tools to withstand high speed rotation and severe wear, ensuring long-lasting performance and consistent results even in demanding grinding applications.

One of the main advantages of diamond grinding tools is their suitability for machining hard materials. Whether grinding metal alloys, ceramics, or stone, diamond grinding tools deliver precise and uniform results even when working with the toughest materials. The high wear resistance and hardness of diamond grinding tools make them ideal for applications where traditional grinding tools have difficulty maintaining their effectiveness.

Additionally, customization options for diamond grinding tools allow tools of different shapes and sizes to be created to meet specific machining needs. This flexibility ensures that each industry can receive a tailor-made solution based on its unique grinding requirements, thereby increasing the overall efficiency and productivity of materials processing operations.

Diamond Drilling Tools

Diamond drilling tools have become essential equipment for precision drilling in hard materials such as concrete and rock. These hard, high-strength tools offer unparalleled wear resistance, high temperature stability, and extended service life, making them an integral part of a variety of drilling applications.

The superior performance of diamond drill bits sets them apart from traditional drill bits, allowing them to meet the challenges of drilling in tough materials with precision and efficiency. The use of industrial diamond and metal powder under high temperatures and pressure during the manufacturing process gives the drill bit excellent hardness and wear resistance, allowing it to withstand high-speed rotation and severe wear during drilling operations.

One of the main advantages of diamond drilling tools is their ability to maintain their sharpness and effectiveness over time. Unlike ordinary drill bits, diamond drill bits are more wear-resistant, ensuring consistent performance and longer life even when drilling the hardest materials. This durability and longevity make diamond drilling tools a cost-effective solution for industrial and construction projects, reducing the need for frequent tool changes.

In addition, the high-temperature stability of diamond drill bits allows them to withstand the heat generated during drilling, ensuring that structural integrity and cutting efficiency are maintained even under harsh drilling conditions. This stability is especially important when drilling into materials that generate large amounts of heat during the drilling process, such as concrete and rock.

Diamond drilling tools are designed to provide precision and efficiency for a variety of drilling applications. Whether drilling into concrete on a construction project or drilling through rock formations in geological exploration, diamond drill bits provide the reliability and performance needed for accurate, clean drilling results.

Characteristics of Diamond Tools

High-Temperature Stability: Diamond exhibits exceptional heat resistance, allowing it to maintain its cutting edge even under extreme conditions.

Wear Resistance: As the hardest known material, diamond offers unparalleled resistance to abrasion and wear, ensuring tool longevity.

High Hardness: Diamond's exceptional hardness enables it to cut through tough materials with ease and precision.

High Precision: Diamond tools produce highly accurate and consistent results due to their sharp cutting edges and dimensional stability.

Chemical Inertness: Diamond is resistant to most chemicals, making it suitable for various working environments.

Thermal Conductivity: Diamond efficiently dissipates heat, preventing tool overheating and improving cutting performance.

English

English  Português

Português  русский

русский  Chinese

Chinese  French

French  Japanese

Japanese  Spanish

Spanish