Misunderstandings and solutions for using diamond wire saws

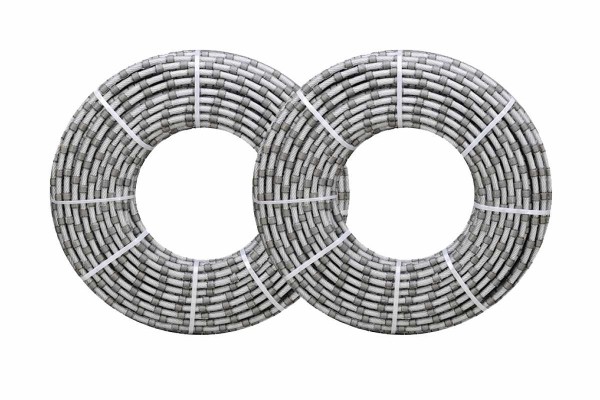

Diamond wire saws have become a popular choice for cutting hard materials due to their advantages such as fast cutting speed, high precision, and smooth cutting surface. However, to ensure optimal performance and safety, potential misunderstandings must be addressed and adequate preparation must be made before using a diamond wire saw. In this article, we will discuss common misunderstandings when using diamond wire saws and provide solutions.

Preparation Before Use Diamond Wire Saws

1. Material analysis and wire selection

Myth: Underestimating the importance of analyzing the material to be cut and selecting the appropriate cutting line.

Solution: Before using a diamond wire saw, it is crucial to analyze the hardness, density, moisture content, and other properties of the material. This analysis will help select the most appropriate cutting wire for a specific material, ensuring efficient cutting and minimizing the risk of wire breakage.

2. Description of cutting process and procedures

Myth: Ignoring clear-cutting processes and procedures leads to low-cutting efficiency and safety risks.

Solution: Before using a diamond wire saw, the cutting process and procedure must be clearly defined. This includes selecting the appropriate cutting method and jigsaw length based on specific cutting requirements. By understanding the cutting process and procedures, unnecessary waste and safety risks can be avoided.

3. Equipment inspection and confirmation

Myth: Ignoring the importance of checking the equipment and confirming the tension, length, and mounting method of the jigsaw before starting a cutting operation.

Solution: Before starting to cut, it is necessary to conduct a thorough inspection of the equipment. This includes confirming the diamond wire saw’s tension, wire saw length, and fixing method to ensure they meet cutting requirements. Adequate equipment preparation is critical to safe and efficient cutting operations.

By addressing these misconceptions and implementing the solutions provided, users can increase the efficiency, safety, and success of their diamond wire saw-cutting operations. Adequate preparation, including material analysis, process clarification, and equipment inspection, is critical to achieving optimal cutting results and minimizing potential risks associated with diamond wire saw use.

Precautions for Diamond Wire Cutting

1. Safety precautions

Safety should be your top priority when using a diamond wire saw. The high cutting efficiency of diamond wire saws can cause material to fly, causing potential hazards and damage. To mitigate these risks, users should adhere to the following safety precautions:

Wear appropriate safety equipment, including goggles, gloves, and other protective gear to prevent potential hazards and ensure personal safety during cutting.

2. Control of cutting depth, tension, and direction

In order to achieve precise and efficient cuts, it is crucial to control the depth of the cut, saw tension, and cutting direction. Following these best practices can help ensure a smooth, successful cutting operation:

Maintain control of the depth of cut and saw tension to prevent the saw from getting stuck or causing damage to the surface of the object being cut. Proper tensioning of the scroll saw is critical to obtaining consistent and accurate cutting results.

Make sure you are cutting in the correct direction to avoid potential problems such as snagging on the jigsaw or damage to the cutting surface. Proper alignment and guidance of the scroll saw are critical to achieving the desired cutting results.

3. Soaking and maintenance of cutting oil

During the cutting process, the use of cutting oil is crucial to reduce the heat and wear generated during the cutting process. Following these best practices can help optimize cutting oil use and maintain scroll saw performance:

Ensure that the wire saw is completely immersed in cutting oil during cutting to facilitate efficient heat dissipation and minimize wear on the wire saw.

Change the cutting oil regularly at specified intervals to prevent overheating and accumulation of impurities that may damage the scroll saw. Proper maintenance of cutting oil is critical to maintaining the performance and life of your scroll saw.

By adhering to these precautions and best practices, users can improve the safety, efficiency, and effectiveness of their diamond wire-cutting operations. Prioritizing safety, maintaining control of cutting parameters, and optimizing cutting oil use are critical to achieving successful and reliable cutting results while minimizing potential risks and issues.

Basic Maintenance Practices for Diamond Wire Saw

1. Clean tools and cutting objects promptly

After using a diamond wire saw, it is important to promptly clean up the fine substances and residues on the surface of the tool and the cutting object. This practice helps prevent the buildup of debris that can damage the scroll saw and affect its performance during subsequent use. Regular cleaning ensures that the wire saw remains in optimal condition for future cutting operations.

2. Replace damaged or worn wire saws promptly

When the diamond wire saw is found to be damaged, it should be replaced in time to maintain cutting accuracy and safety. Additionally, if a wire saw shows signs of excessive wear, it should be replaced to ensure consistent cut quality and efficiency. Regularly checking the condition of your scroll saw is essential to identify any damage or wear and take appropriate action to maintain optimal cutting performance.

3. Proper storage environment

When storing a diamond wire saw, it is important to place it in a dry and ventilated environment to prevent moisture buildup and minimize the risk of rust or chemical damage. Storing your scroll saw in the right environment will help maintain its integrity and extend its lifespan, ensuring it remains in top condition for future use.

By adhering to these maintenance practices, users can extend the life of their diamond wire saws, maintain cutting accuracy, and ensure safe and efficient cutting operations. Regular cleaning, timely replacement of damaged or worn wire saws, and proper storage are critical to maintaining the performance and longevity of your diamond wire saw, ultimately contributing to successful cutting results and user safety.

English

English  Português

Português  русский

русский  Chinese

Chinese  French

French  Japanese

Japanese  Spanish

Spanish