What is the current trend on countertop edges?

Countertops play a key role in the aesthetics and functionality of furniture and interior design, and rounded edges are a key element that enhances the visual appeal and practicality of countertops. When considering the processing of countertops, the choices of rounded corners and compound edge rounded corners show obvious differences, each meeting specific needs and scenarios. This article aims to clarify the differences between these two methods and provide insight into their respective applications and advantages.

Rounded Corners of Countertops

Countertop fillets represent a basic treatment that can improve the safety and aesthetics of a variety of countertop materials, including stone, wood, glass, and more.

1. Safety and practicality: reduced crash risk and improved comfort

The process of creating fillets by sanding directly onto the edge of the countertop is a key safety measure that minimizes the risk of collision with sharp corners and edges. This treatment is especially important in environments where safety and practicality are critical, such as kitchens, bathrooms, and high-traffic areas. By rounding off countertop corners, the risk of accidental collisions and injuries can be significantly reduced, resulting in a safer, more comfortable living and working environment.

2. Aesthetic and visual appeal: Enhance the overall look and feel

In addition to safety benefits, countertop rounded corners also play a key role in enhancing the overall aesthetics and visual appeal of the countertop. Smooth rounded edges create a sleek and modern look, creating a seamless and inviting look that complements a variety of interior design styles. Whether it is a residential kitchen, commercial space, or decorative furniture, the aesthetic impact of countertop fillets is undeniable, adding a touch of elegance and sophistication to the overall space.

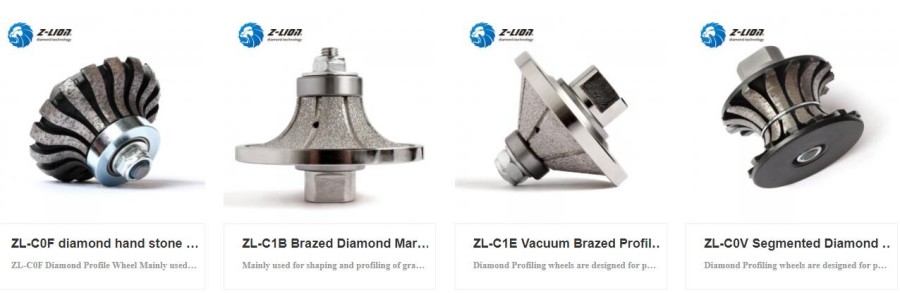

3. Professional grinding tools: Choosing the right equipment for the job

When filleting countertops, choosing a professional grinding tool is crucial to achieving the desired curvature and finish. Depending on the specific material and processing requirements, different sandpapers, abrasives, and other tools may be required to achieve the desired results. For example, diamond polishing pads and profiling wheels are commonly used on stone countertops, while specialized sanding and polishing tools are used on wood and glass surfaces. Carefully selected grinding tools ensure that the countertop rounding process is suited to the unique characteristics of the material, resulting in a precise and visually appealing finish.

4. Master grinding techniques: Ensure consistency and beauty

In addition to using the right grinding tools, mastering grinding techniques is crucial to achieving a consistent, smooth, and beautiful countertop round. Applying consistent pressure, maintaining a steady grinding speed, and meticulous attention to detail are key aspects of mastering the grinding technique. Whether achieving an even curvature or improving a surface finish, the expertise and precision of grinding technology help ensure that countertop fillets meet the highest quality and aesthetic standards.

Composite Edge Bonding and Rounding

Countertop composite edge bonding and rounding represent a sophisticated treatment that adds a new dimension of customization and visual appeal to countertop designs.

1. Enhanced customization and special effects: the nature of composite edge bonding and rounding

Countertop composite edge bonding and rounding involves the process of adhering one or more layers of material to the edge of the countertop and then rounding the corners of those materials. This treatment is particularly suitable for countertops that require a high degree of customization and special effects, providing a versatile way to achieve unique design elements and visual impact.

2. Complexity and precision: solving the complexities of composite edge bonding and rounding

Different from traditional countertop rounding, edge rounding of composite materials presents a more complex and precise processing technology. Careful selection of materials, precise bonding techniques, and meticulous attention to detail are important aspects in achieving a seamless and visually appealing result. By handling complex composite edge bonding and rounding, professionals can ensure each countertop meets the highest quality and customization standards, resulting in a finished product that is visually striking and unique.

3. Material selection and design flexibility: Customize countertops to unique specifications

The composite edge bonding and rounding process provides unparalleled design flexibility, allowing the combination of different materials, textures, and colors to achieve unique custom countertop designs. Whether natural stone, engineered surfaces, or the integration of decorative elements, the versatility of composite edge bonding and rounding allows designers and homeowners to customize countertops to their unique specifications, resulting in visually striking, one-of-a-kind Finished products.

4. Aesthetic impact and visual appeal: taking countertop design to new heights

By embracing the complexities of bonding and rounding composite edges, professionals can enhance the overall aesthetic impact and visual appeal of the countertop. The seamless integration of multiple materials and precise fillets helps create a visually striking and sophisticated finish that adds a touch of elegance and exclusivity to interior spaces.

5. Selecting the appropriate bonding material: customized based on material and durability requirements

When undertaking the process of gluing and rounding countertop edges, the first step involves selecting the appropriate bonding material, such as wood veneer, metal veneer, PVC, or other suitable materials. These materials must match the countertop material and be strong and durable enough to ensure a seamless and long-lasting bond. Careful selection of bonding materials is critical to achieving a uniform and visually appealing result that complements the overall design of the countertop.

6. Ensure a strong bond: Use the appropriate adhesive for durability and stability

Once the materials have been selected, the next step is to adhere them to the countertop edges using an appropriate adhesive to ensure sturdiness, durability, and stability. Adhesive selection is critical to ensuring a strong and long-lasting bond between the countertop and additional materials, contributing to the overall structural integrity and longevity of the finished product. By using the right adhesive, professionals can ensure that the bonding process adheres the material to the countertop edge seamlessly and securely.

7. Rounding the glued material: for a uniform and beautiful finish

Once the bonding process is complete, the next step is to round off the bonding material to form a unified whole with the main part of the countertop. This step requires precision and mastery of sanding techniques to ensure a consistent, smooth, and beautiful edge. By practicing and perfecting grinding techniques, professionals can create visually striking and seamless transitions between countertops and additional materials, resulting in a cohesive and visually appealing finished product.

Countertop Rounded Corners Vs Composite Edge Bonding

Advantages of composite edge bonding

Compared with the rounded corners of the countertop, the advantage of composite edge sealing on the countertop is that it can achieve more complex and diverse appearance effects. By choosing different bonding materials and filleting methods, designers can create unique visual and tactile experiences that add a touch of elegance and sophistication to the overall countertop design. In addition, composite edging can enhance the structural strength and durability of the countertop to a certain extent, making it ideal for highly customized and special effects.

Limitations of composite edge bonding

However, there are some limitations to composite countertop edging. First of all, the processing accuracy and technical requirements are high, resulting in relatively high processing costs. Second, due to potential differences in the properties of bonded materials, special attention needs to be paid to the selection and use of adhesives to ensure long-term stability and reliability. Additionally, compatibility issues may arise between adhesive materials and certain specialty countertop materials, requiring additional testing and verification.

Advantages of countertop rounded corners

In contrast, countertop fillets offer a more straightforward, traditional way to enhance the aesthetics and safety of your countertops. The technology prioritizes precision and beauty, helping to create a sleek and modern look while prioritizing safety and comfort. Countertop rounded corners are ideal for a variety of interior design styles and applications, providing a seamless and inviting look.

Design and application considerations

When considering the choice between countertop fillets and composite edge bonding, specific design requirements, desired visual impact, and living or work space requirements must be weighed. While composite edge bonding provides enhanced customization and special effects, countertop fillets provide a timeless and versatile aesthetic. By carefully considering these factors, designers and homeowners can make informed decisions based on their unique preferences and specific requirements for countertop design.

English

English  Português

Português  русский

русский  Chinese

Chinese  French

French  Japanese

Japanese  Spanish

Spanish